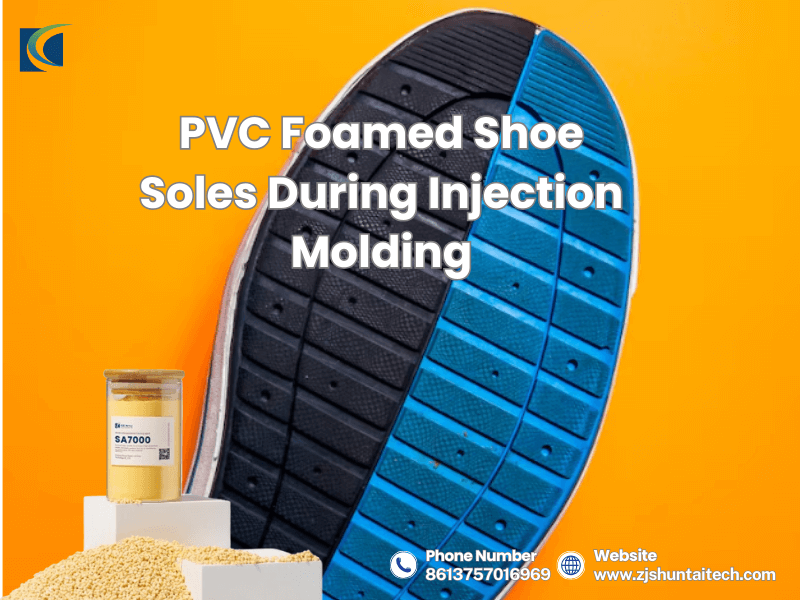

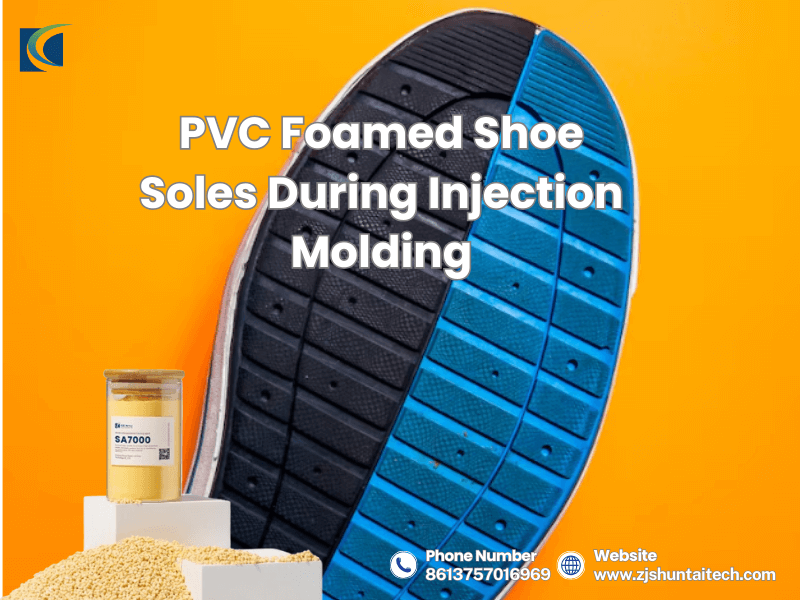

In the footwear industry, PVC foamed soles hold a significant market share due to their low cost, lightweight properties, and wear resistance.However, during injection molding, poor flowability and insufficient resilience of PVC foamed soles often become critical issues affecting product quality. Poor flowability leads to incomplete mold filling, resulting in defects like short shots and sink marks. Insufficient resilience causes soles to deform and crack easily, shortening their service life.

Root Causes of Poor Flow and Toughness in PVC Foam Soles

3 Key Reasons for Poor Flow

1. Imbalanced Material FormulationPVC foam sole materials consist of resin, plasticizers, foaming agents, fillers, etc. Improper ratios of any component can affect flow.For instance, excessive filler (like calcium carbonate) increases material viscosity, hindering flow; incorrect plasticizer selection or insufficient dosage reduces PVC molecular chain mobility, making it difficult to fill complex mold cavities; unstable decomposition rates of foaming agents or uneven gas distribution also disrupt material flow trajectories.

2. Unreasonable Injection ParametersTemperature, pressure, and speed are the “three key elements” of injection molding. Deviations in any parameter can trigger flow issues. At too low a temperature, PVC fails to fully melt, remaining in a solid or semi-solid state that impedes smooth flow. Excessive heat causes material degradation, producing impurities that clog flow channels.Insufficient injection pressure fails to push material into narrow mold gaps; excessively slow injection speeds cause premature cooling and solidification during flow, resulting in “incomplete fill.”

3. Inadequate Mold Design and MaintenanceThe mold serves as the “channel” for material flow, and design flaws directly impede this flow.For instance, an undersized gate significantly increases flow resistance; sharp corners or complex undercuts in the cavity create flow dead zones; blocked or insufficient vent holes trap gas within the cavity, compressing the material flow space. Additionally, accumulated residual material on the mold surface increases flow friction.

Core Factors Affecting Insufficient Toughness

1. Uneven Foam StructureThe toughness of PVC foam soles relies on uniform foam cell structure. If temperature fluctuations affect the decomposition of the foaming agent, cells of varying sizes are produced—large cells create loose structures prone to deformation under stress, while overly dense small cells result in excessively rigid, inelastic material. Simultaneously, moisture within the material can interfere with foaming agent decomposition, forming voids or bubbles that become weak points in toughness.

2. Insufficient Polymer Matrix StrengthThe inherent properties of PVC resin directly determine matrix strength. Resins with low molecular weight and high impurity content exhibit weak intermolecular bonds, making them vulnerable to external impact. Without crosslinking agents or with insufficient quantities, PVC chains fail to form a stable network structure, resulting in poor elastic recovery. This leads to permanent deformation under pressure.

3. Injection molding defects compromising toughnessDefects like bubbles, delamination, and sink marks during injection molding disrupt the sole's structural integrity. For instance, bubbles create “hollow zones” within the sole, causing internal fractures under stress; delamination separates the surface layer from the core, leading to direct cracking during bending.

Practical strategies to enhance PVC foam sole flowability

To address these issues, systematic optimization of flowability can be achieved through three approaches: material selection, process parameters, and mold design, thereby reducing injection defects.

Optimizing Material Formulation: Reducing Flow Resistance at the Source

1. Selecting PVC ResinPrioritize PVC resin with medium molecular weight (polymerization degree 1000-1200). This resin type features moderate molecular chain length, ensuring adequate strength while maintaining good flowability.Simultaneously, control resin impurity content (ash ≤0.3%) to prevent channel blockages.

2. Scientifically Adjust PlasticizersSelect plasticizers with high compatibility with PVC, such as di-n-octyl phthalate (DOP) or di-n-octyl adipate (DOA). These plasticizers effectively weaken intermolecular forces in PVC chains, reducing material viscosity.The plasticizer dosage must be controlled at 30-35 phr (parts per hundred resin). Too little will result in excessively hard material with poor flow, while too much will reduce the sole's strength.

3. Incorporate Flow PromotersAdding 1-2 phr of flow aids like calcium stearate or polyethylene wax forms a lubricating layer on PVC molecular surfaces, reducing intermolecular friction. Polyethylene wax additionally enhances thermal stability, preventing degradation-induced flow impairment at elevated temperatures.

4. Control Filler and Foaming Agent DosageFiller usage should not exceed 20 phr, preferably using fine-particle (2000 mesh or finer) lightweight calcium carbonate to minimize flow resistance. Select azodicarbonamide (AC) as the foaming agent due to its stable decomposition temperature (190-210°C) and uniform gas release, which avoids disrupting material flow. Control usage at 1-1.5 phr.

Fine-Tuning Injection Parameters

1. Zone-Specific Temperature ControlSet barrel temperatures using “gradient control”: Feed section 140-160°C (prevents premature resin melting and clumping), Melting section 160-180°C (ensures complete material melting), Nozzle section 170-190°C (prevents material cooling at the nozzle).Simultaneously, preheat the mold to 40-60°C to reduce the temperature difference between material and mold surface, preventing excessive cooling.

2. Optimize Pressure and SpeedAdjust injection pressure based on mold complexity, typically set at 80-120MPa. For intricate molds, increase to 130MPa as needed to ensure material fills fine cavities.Injection speed employs a three-stage “slow-fast-slow” control: - Initial stage: Slow (20-30 mm/s) to prevent gas entrapment - Intermediate stage: Fast (50-70 mm/s) to enhance filling efficiency - Final stage: Slow (10-20 mm/s) to prevent overflow.

Optimize holding pressure and time settingsSet holding pressure to 50-70% of injection pressure (approx. 40-80 MPa) with a holding time of 5-10 seconds. This compensates for material shrinkage during cooling and ensures complete mold filling. Insufficient holding pressure causes shrinkage marks, while excessive holding time increases mold pressure, complicating demolding.

Improve mold design and maintenance

1. Optimize gate and cavity structuresEmploy fan gates or edge gates with widths of 5-8mm and thicknesses of 2-3mm to reduce flow resistance. In cavity design, replace sharp corners with radii ≥3mm to eliminate flow dead zones. Complex undercuts should be split or utilize core-pulling mechanisms to ensure complete material filling.

2. Enhance Mold VentingAdd vent holes at the end of mold filling and at corners. Vent holes should be 0.01-0.02mm thick and 5-10mm wide to ensure timely gas escape. For large molds, install one vent hole per 100mm to prevent gas accumulation.

3. Regular Mold MaintenanceBefore daily production, wipe the mold surface with a specialized cleaner to remove residual PVC waste. Weekly inspect gates and runners for wear; repair or replace immediately if deformation or blockage occurs. Apply rust prevention treatment monthly to extend mold lifespan.

Effective Methods to Enhance PVC Foam Sole Toughness

Strengthen Polymer Matrix

1. Add Crosslinking AgentsIncorporate 0.5-1 phr of diisopropylbenzene peroxide (DCP) as a crosslinking agent in the formulation. DCP initiates PVC molecular chain crosslinking at high temperatures, forming a three-dimensional network structure that enhances material elasticity and deformation resistance. Note: Crosslinking agent dosage must not exceed limits, as excessive amounts will cause material hardening and loss of toughness.

2. Incorporate Elastomeric ModifiersIncorporate 5-10 phr of elastic polymers such as nitrile rubber (NBR) or ethylene-vinyl acetate copolymer (EVA). These materials form a blend system with PVC. Upon impact, the elastic modifier absorbs energy, reducing the risk of material fracture. EVA additionally improves PVC's low-temperature toughness, making it suitable for winter shoe soles.

3. Select high-elasticity foaming agentsFor soles requiring high toughness (e.g., athletic shoes), use a composite foaming agent of sodium bicarbonate and citric acid. Its low decomposition temperature (120-140°C) produces fine, uniform foam cells (50-100μm diameter) with a dense structure and superior elastic recovery.

Ensure uniform foam structure

1. Control foaming agent decomposition conditionsPrior to production, place the PVC compound in a vacuum dryer (temperature 80-90°C, duration 2-3 hours) to remove moisture (moisture content ≤0.1%), preventing water interference with foaming agent decomposition. Simultaneously, incorporate 0.5-1 phr of talc as a nucleating agent into the formulation. This provides uniform “nuclei” for foam cell formation, preventing the emergence of large cells.

2. Optimize Foaming Stage Temperature and Cooling TimeMaintain mold temperature at 50-60°C to ensure complete decomposition of the foaming agent. Extend cooling time to 15-20 seconds, allowing foam cells to stabilize and form properly. If cooled too rapidly, foam cells may rupture before setting, creating voids. Conversely, excessively slow cooling reduces production efficiency.

Reducing Injection Molding Defects

1. Preventing Gas EntrapmentBeyond optimizing mold venting, pre-plasticize PVC compound before injection to expel trapped air. Employ “segmented venting” during injection: pause for 1-2 seconds when filling reaches 70% of the cavity, allowing gases to fully escape before resuming filling.

2. Avoid Excessive FoamingStrictly control foaming agent dosage. Excessive foaming agent causes over-expansion of foam cells and structural loosening. Simultaneously, maintain barrel temperature within the foaming agent's decomposition range to prevent rapid decomposition at high temperatures, which generates excessive gas and disrupts foam structure.

3. Addressing DelaminationFor multi-layer injection-molded soles, incorporate 0.3-0.5 phr of adhesion promoter (e.g., chlorinated polyethylene) into each layer to enhance interlayer bonding. During injection, ensure consistent temperature across all layers to prevent delamination caused by thermal variations.

Future Trends

To enhance the flowability and toughness of PVC foam sole injection molding, synergistic optimization across material formulation, injection parameters, and mold design is essential. Scientific testing and real-time control ensure effective implementation. This approach not only reduces production defects and boosts efficiency but also elevates product competitiveness, meeting consumer demands for “comfortable and durable” soles.

Looking ahead, as environmental standards tighten,

chemical foaming agents will enable green production while maintaining flow and toughness. Further precision improvements will help PVC foam soles achieve a better balance between resilience and lightweight properties.

If you encounter flow or toughness issues in PVC foam sole injection molding, feel free to consult

shuntaitech. We offer customized optimization solutions for foaming agents.