Ethylene-vinyl acetate (EVA) foam is a closed-cell foam material that has gained widespread use across various industries. EVA foam is a copolymer made by combining ethylene and vinyl acetate, resulting in a resilient, flexible material. EVA foam is often used as a substitute for natural rubber, vinyl, and other foam materials because it offers a unique combination of properties that make it incredibly versatile.

The chemical composition of EVA foam consists primarily of ethylene and vinyl acetate, mixed in varying ratios to produce foams with different characteristics.

EVA foam consists primarily of ethylene and vinyl acetate mixed in different ratios to produce foams with various characteristics. The ratio of these components determines the foam’s properties, such as flexibility, density, and resilience. In addition to these base materials, EVA foam often includes additives such as colorants, UV stabilizers, and other agents that enhance its performance and appearance.

EVA foam is quite versatile when it comes to physical properties. Its density can range from 33 to 280 kg/m³. Additionally, its hardness levels can range from 15 to 80 degrees on the Shore C scale. This wide range of properties makes EVA foam extremely adaptable and suitable for many applications, from lightweight packaging to heavy-duty industrial components.

EVA is an amorphous plastic that is environmentally friendly and non-toxic, with a shrinkage rate of 2% and a density of 0.95 g/cm², making it lighter than water. It has poor surface gloss, low mechanical strength, good elasticity, excellent flow properties, and is easy to process and form. Depending on the content of vinyl acetate in EVA, it is widely used in various applications such as infant and children's toy wheels, films, composite films, various molded products, adhesives, and more.

EVA foaming is categorized into three types: traditional large-scale flat foaming, in-mold small foaming, and injection molding.

The formulation for EVA foaming primarily consists of: main materials (EVA, PE), POE, TPR, foaming agents, crosslinking agents, zinc stearate, and colorants. Generally, different EVA foaming formulations can be tailored based on the product's size, dimensions, and color requirements.

EVA foam is available in varying densities, each suited to different applications based on the required level of cushioning and rigidity. High-density EVA foam is often used for durable, impact-resistant applications, such as industrial equipment cases or athletic padding, while lower-density foam is typically used for softer, more flexible products, like custom insoles or toy parts.

Comparing foam densities is essential for selecting the appropriate material for each application. EVA foam is commonly categorized into the following types:

(1) High-performance EVA foam: Used in sports equipment, automotive components, and high-end consumer products

(2) Closed-cell foam: Due to its moisture resistance, this type is ideal for outdoor gear and marine applications.

Antioxidants: Prevent oxidation during processing and use.

UV stabilizers: Protect the material from UV exposure.

Plasticizers: Enhance flexibility and processability, making the material suitable for producing high-density EVA foam and EVA foam inserts.

Blowing agents: Used in the foaming process to create foam structure.

Fillers: Examples include calcium carbonate and talcum powder, which improve material strength and reduce costs.

The EVA foam manufacturing process involves several key stages, from preparing the raw materials to producing the final product. Various foam extrusion methods and polymer processing technologies are utilized to ensure high-quality output.

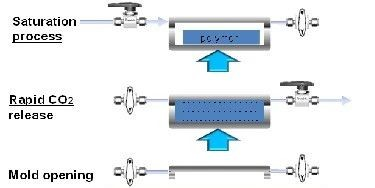

The EVA foam manufacturing process is a multi-step procedure that begins with mixing the raw materials in a Banbury mixer. Next, the material is extruded into sheets or rolls. Finally, an EVA mold foaming vulcanizing machine carries out the foaming process, giving the material its characteristic closed-cell structure. These processes can be customized to produce EVA foam with specific properties, making it ideal for specialized applications.

There are several different production processes for EVA (ethylene-vinyl acetate copolymer), including extrusion molding, foam molding, hot pressing, injection molding, coating, and hot melt adhesive molding. The first four are primarily used in the carrying case industry.

Once the EVA plastic pellets are prepared, the appropriate amounts of blowing agents and stabilizers are added. After the materials are mixed evenly, they are sent to a melting machine to be heated and melted.

To produce films, EVA sheets, and profiles: The mixed raw materials are heated in an extruder with a barrel and screw. The mixture is extruded through long or sheet molds to form strips or rolls of foam. The foam is rapidly cooled and solidified in a cooling water channel after extrusion.

For protective cushioning products like EVA inserts, the mixed raw materials are placed in a foam molding heating machine (with hot air or steam) to produce gas and expand the material. The mixture is then poured into closed molds of specific shapes while maintaining stable pressure, and is heated until it cools and can be cut.

For EVA shell material for case bodies and thicker EVA products, the mixed raw materials are placed in a large roller mold with upper and lower molds using electric heating. The materials are compressed under the effects of heat, which produces numerous bubbles and expands the material into foam. Higher temperatures yield larger bubbles and lower hardness. The longer the compression time, the denser the foam. The materials are then rapidly cooled through a cooling channel.

is used to produce complex-shaped parts and inserts. Mixed plastic pellet materials are heated in an injection machine and injected into fixed and moving molds with complex designs to ensure precise, high-quality surfaces for custom products.

The processing method chosen depends on the final product's specific requirements, including fillers and additives. Different types of fillers, such as calcium carbonate and talcum powder, as well as other chemical additives, like plasticizers, can alter the foam's hardness and other physical properties, including density, flexibility, and durability.

EVA (ethylene-vinyl acetate copolymer) boasts unique chemical properties that give it exceptional advantages and characteristics in the materials field. In terms of performance, EVA has excellent flexibility and elasticity, and its flexibility increases with higher VA content. It can be used in a wide range of applications. It also has good shock absorption and cushioning properties, and it can effectively absorb impact force. It plays an important role in the packaging of electronic products and the soles of sports shoes. In terms of chemical stability, EVA EVA is water- and oil-resistant and UV-resistant, and it can maintain its performance stability in complex environments such as wet and outdoor environments. Additionally, EVA has excellent processing performance and can be produced in different shapes and densities through various processes such as extrusion, molding, and injection molding to meet diverse needs. Furthermore, EVA can be combined with other materials to expand its application range. EVA is a highly competitive material choice for both industrial manufacturing, which requires high-performance products, and the consumer products sector, which prioritizes user experience.

Thanks to its distinctive combination of lightweight durability, cushioning, and flexibility, EVA (ethylene-vinyl acetate) foaming technology has unlocked versatile applications across industries. In the manufacturing of footwear, EVA’s superior shock-absorbing and anti-slip properties make it a staple for mid-to-high-end shoe components, especially soles and insoles for travel shoes, hiking boots, slippers, and sandals. Its adaptability ensures comfort and support in a variety of designs.

In sports and fitness, EVA’s impact-resistant nature drives its use in protective gear and equipment. It is widely used to make helmets, knee and elbow pads, and sports mats that provide reliable cushioning during high-impact activities. Yoga mats and exercise flooring made from EVA further demonstrate its ability to enhance user safety and comfort.

Beyond apparel and sports, EVA foaming extends to everyday consumer goods. Its buoyancy and shock-absorbing capabilities are leveraged in lightweight bags, flotation devices, and protective cases for electronics, such as smartphones and tablets. These products shield devices from drops and scratches while adding minimal bulk, aligning with modern design preferences for sleek, functional accessories.

In summary, mastering the formulation components and processing technologies of EVA foaming is pivotal for delivering superior-quality products in today’s competitive market. As the industry continues to innovate, keeping pace with these technical nuances will be crucial for sustained excellence and market leadership.

With over 16 years of expertise in the field, Shuntai Foaming Agents specializes in manufacturing high-performance AC foaming agents. Our solutions are designed to optimize foaming efficiency, stability, and product consistency across diverse applications, from footwear and sports equipment to industrial materials.

Request a Free Sample: Experience the performance of our AC foaming agents firsthand.

Technical Consultation: Get tailored insights from our team of industry specialists.

Contact us today to explore how Shuntai’s advanced foaming solutions can drive innovation and efficiency in your production line. Let’s shape the future of EVA foaming together.

Get Quotation: 8613757016969