In the building decoration, furniture manufacturing, advertising display and many other industries, PVC foam board with its light weight, heat insulation, sound insulation, easy to process and other advantages, has become a favored material. However, in the production process of PVC foam board, often encountered such as “thick in the middle and thin on both sides”, the surface of the bubble silver lines, poor plasticization and a series of problems, these problems not only affect the quality of the product, but also reduces the production efficiency and increase the cost of enterprises.

PVC foam board common problems and causes of analysis

Uneven thickness

“thick in the middle and thin on both sides” is the most prominent uneven thickness in the production of PVC foam board. This phenomenon is closely related to the production process, raw material formula, equipment and other factors. From the production process point of view, the uneven temperature control in the extrusion molding process is the key factor. If the die head temperature shows “high in the middle, low on both sides” of the distribution state, will lead to the melt in the middle of the region of the flow rate is fast, the flow rate of the two sides of the slow, resulting in the sheet in the middle of the thick side of the two thin; cooling system design is unreasonable, such as the two sides of the cooling rate is significantly faster than the middle, but also make the sheet shrinkage is not consistent, exacerbating the thickness deviation.

In terms of raw material formulation, the difference in resin melt fluidity has a significant impact on thickness uniformity. Elected to use a wider molecular weight distribution of PVC resin, the melt viscosity in the middle and the two sides of the viscosity will be different, resulting in inconsistent flow rate; foam, stabilizers and other additives are not added inaccurately or unevenly mixed, will make the foam multiplier in different parts of the sheet to produce differences, will also cause thickness problems.

Equipment and mold factors can not be ignored. Defects in the design of the die head structure, such as runner width, compression ratio is not reasonable, will make the melt in the die head distribution is not uniform; mold wear after long-term use, or the installation of the two sides of the pressure is not consistent with the middle, resulting in changes in the gap between the die lip, will affect the thickness of the plate uniformity . In addition, the mismatch between haul-off speed and extrusion speed, so that the two sides of the sheet are subject to excessive stretching, as well as uneven force during stacking and transportation, may also cause abnormal thickness of the sheet.

Surface quality problems

PVC foam board surface bubbles, silver grain and other problems, seriously affecting the product appearance and performance. This is mainly related to the state of calcium carbonate filler in the raw material and the production process. Calcium carbonate as a common filler for PVC foam board, its particle size distribution and dispersion of the state of the melt strength has an important impact. When the particle size of calcium carbonate is too large or too small, it will lead to uneven mixing, prolong the plasticizing time, reduce the screw torque, and make the surface of the sheet defective. In the rainy season and other humidity environment, calcium carbonate is easy to absorb moisture, damp calcium carbonate will form bubbles and silver lines on the surface of the sheet, not only affect the appearance, but also change the flow characteristics of the melt, indirectly affecting the thickness of the sheet uniformity .

Problems of poor plasticization

Defective plasticization is characterized by roughness on the surface of the sheet, loose internal structure, and so on. This problem is closely related to the imbalance of lubricant system. When the amount of internal lubricant is insufficient, the dispersion of the material in the extruder becomes poor, the uniformity of plasticization is reduced, resulting in insufficient plasticization; and when the amount of internal lubricant is too much or the external lubricant is not used properly, it may result in over-plasticization, so that the strength of the melt decreases, and it is difficult to maintain a uniform expansion of the foaming, which affects the quality of the sheet. In addition, the raw material formula of the additives in the proportion of the imbalance, as well as the production process parameters are not set reasonably, such as temperature, screw speed and other control is not appropriate, will also lead to poor plasticization problems.

6 general knowledge of PVC foamed board processing

Processing Characteristics and Cost Control: The processing characteristics of PVC Foam Boards are similar to those of timber processing, and it is necessary to avoid scorching caused by high working temperatures. The debris generated from processing can be collected and recycled to reduce production costs. When cutting hollow foam boards, it is important to note that the 23mm hollow space allows for easy assembly, and pins can be used for positioning to improve processing convenience.

Carving and molding and surface treatment: According to the design drawings, the PVC foamed board can be molded with a carving machine, and then the surface can be pasted with melamine board or baked paint treatment. It should be noted that if the surface of the hollow foam board is not flat, only 2mm PVC board can be used as the material for vacuum overmolding.

Scope of application of bending molding: Bending molding is only applicable to solid foam board, not applicable to hollow foam board. The specific processing method is to use the upper and lower molds, cover the aluminum plate on the surface of the wooden mold, heat the solid foam board to the plasticizing temperature of 70 - 90°C, during the process, squeeze the surface of the foam board directly through the upper and lower molds, and there should not be other operations interfering with the extrusion process.

Self-adhesive PVC surface texture treatment: During the manufacturing process of self-adhesive PVC, different textures of woodgrain patterns can be printed on the surface according to demand, which can eliminate some unnecessary processing procedures.

Baking paint treatment type and characteristics: PVC foaming board surface can be baked paint treatment, according to different processing methods, generally can be divided into ordinary baking paint, piano baking paint and ceramic baking paint. Piano baking varnish will add anti-ultraviolet components during processing to prevent surface discoloration; in terms of surface hardness, ceramic baking varnish is the best performance, with the advantage of anti-scratch.

Surface Paste and Edge Sealing Processing: The common processing method is to paste crystal board (usually one-sided colored acrylic board), melamine board or melamine paper on the surface of PVC foamed board. Edge sealing part is mostly processed by automatic edge sealing machine, which is mainly of two types: roller type and crawler type. If hollow foam boards are used, it is recommended to choose edge sealing materials with similar color to the surface covering materials to avoid obvious color difference caused by shrinkage of the paper after pasting. In addition, the drilling operation is more favorable to the tracked edge banding machine, which can reduce the unevenness of the surface after edge banding, while the pressure adjustment is also crucial. Foam boards can also be drilled directly through CNC machines and can be used to reduce the density of the material itself and increase the air content according to the actual application requirements, thus realizing thermal and acoustic insulation and reducing costs, for example, 15mm foam boards can be reduced in weight to the same weight as 10mm foam boards of the same volume.

PVC foamed board inspection precautions

Quality requirements of the board surface: the surface of high-quality PVC foamed board should feel smooth and flat, without obvious mechanical texture, no color difference on the surface, milky white, no stains, small pits, pinholes, coarse pinholes and cracks. It should be noted that non-milk-white foam boards are mostly made of waste boards recycled in depth, which are not environmentally friendly boards, and environmentally friendly boards do not contain lead (lead content is lower than the European and American standards).

Board side board quality requirements: board side board cut should be flat, fine air holes, no pinhole, coarse holes, serious powder fall and honeycomb hole phenomenon, the cut fiber should be natural shedding, will not pop up. If the above bad conditions occur, it will bring trouble to the subsequent process of finished product production.

Thickness Measurement Standard: When measuring the thickness of PVC foaming board with caliper, the caliper and the board surface should be closely fit without gap, and the thickness of the left and right side of the board should be even. Judge the thickness deviation by measuring the left, center and right position of the plate, under normal circumstances, the thickness deviation is within ±0.2mm.

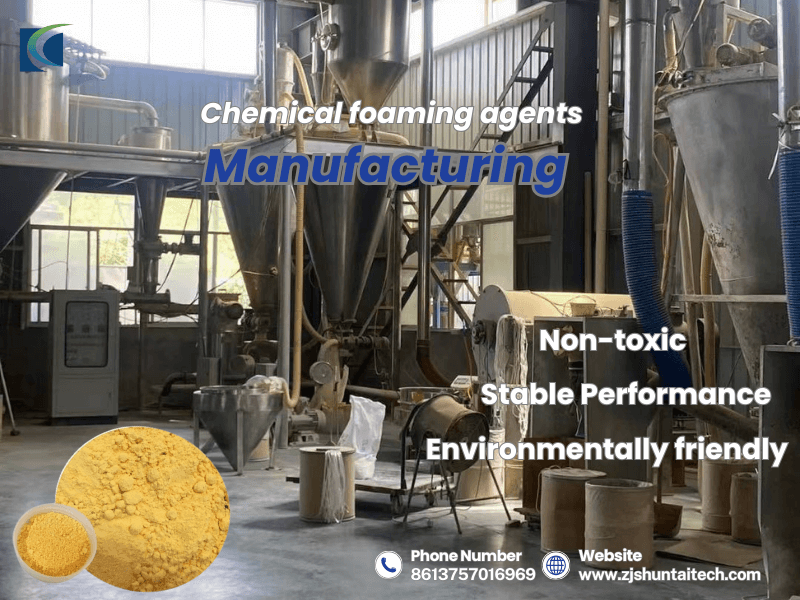

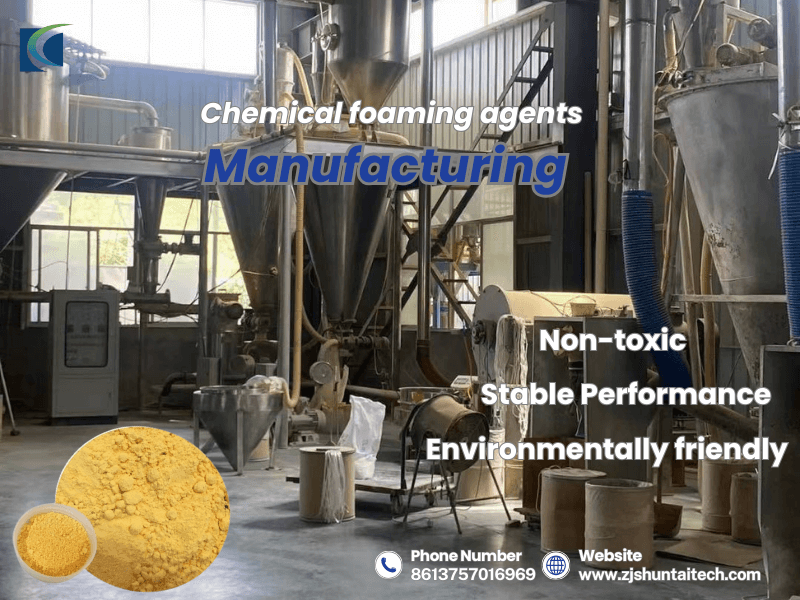

In the process of PVC foam board production towards intelligent, green and whole industry chain synergistic development, the foaming agent as a key additive, its performance directly affects the quality and production efficiency of the board.Shuntai, as a professional chemical blowing agent manufacturer in China, focuses on the research and development and production of AC blowing agent, which, by virtue of the stable decomposition temperature, high efficiency of the gas generation volume and the uniformity of foaming effect, can significantly optimize the foaming process of PVC foam board. The foaming process of PVC foam board. Whether it is to solve the problem of uneven thickness of “thick in the middle and thin on both sides” or to improve the surface quality and plasticizing effect,

AC blowing agent can be well adapted to all kinds of raw materials and process parameters. Choosing our AC blowing agent is not only choosing a high-quality product, but also choosing a set of all-round quality improvement program from raw material end to production end, which can help enterprises win the first chance with excellent product quality in the fierce market competition, and jointly promote the high-quality development of PVC foam board industry.